Constitutive law determination

Better prediction of materials’ service life behaviour enables faster material development, and optimized performance at lower cost. This prediction can be enabled via the determination of constitutive laws governing materials’ behaviour. When materials are used in harsh environments like at high temperatures under specific chemical environments, knowledge of these constitutive models in the service environment is instrumental in predicting their performance.

High temperature indentation testing, in controlled environments, can be used to identify the constitutive law parameters for the mechanical behaviour of coatings up to 1000°C.

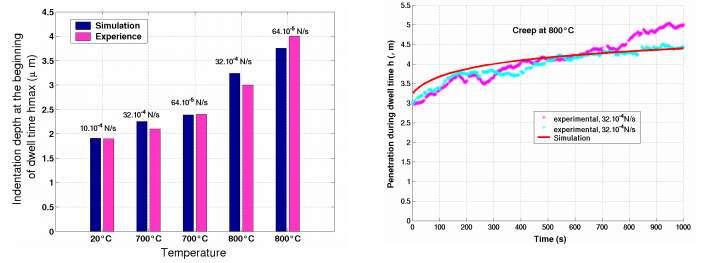

In combination with instrumented indentation experiments performed at various temperatures and loading rates, the unified visco-plastic formalism developed by Chaboche et al. allows a complete description of yield, creep, stress relaxation, and a variety of other mechanical effects, such as Bauschinger effects and time recovery. This formalism uses a superposition of several kinematic hardening models, each incorporating strain hardening, and dynamic and thermal recovery.

This analysis results in a complete time dependent description of the behaviour of materials like NiAlPt coatings as shown in the example below.

Figure 1 : Comparison between simulation and experience at four different temperatures and three different loading rates

Courtesy A. Villemiane

The results on NiAlPt alloy show that iterative identification of the material’s parameters can predict the behaviour of this alloy at 3 temperatures under various loading conditions.