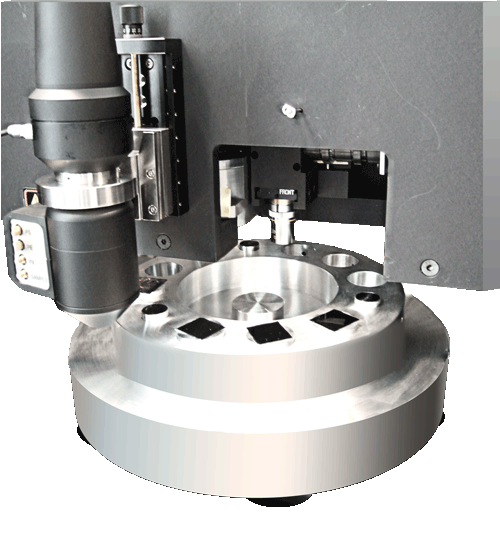

The goal of this design is to allow nanoindentation user's to generate a high quality image of an indent just after the test.

Minimizing the generation time of the image is critical since the material can present time dependent deformation properties.

Using a real AFM with the best adapted cantilever avoid compromizes between indentation and image and associates two complementary techniques in the same instrument.

In other words, we can obtain the best performances on the two different techniques in the same instrument

This exemple shows a Si indent image obtained just after the test with a 95-200 DME model. We can clearly see the sliding stripes corresponding of the cristallographic orientation of the material.The stripes orientation is verified by the modelisation.